Our vision

We aim to provide safe, sustainable and excellent services to our clients and stakeholders. We strive to seek new opportunities and markets without comprising our values.

Meaningful for

our clients

12

Experience

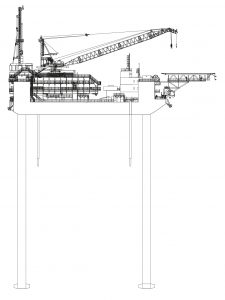

1

Drilling Rig

8

LTI Free Years